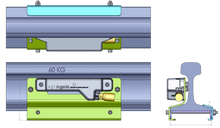

Axle counters are the mainstay of train detection. The Argenia Digital Axle Counter is our most cost-effective unit. The sensor itself mounts on the rail with a mounting bracket. A Wayside Controller Unit (WCU) is mounted nearby which has the electronics to control the collection of train data and provides the axle counting function. The data is sent via a reliable wireless Frequency Hopping Spread Spectrum (FHSS) radio or by a RS485 twisted pair back to the SilverHawk evaluator. Up to 32 WCU units can share the same 4 wire bus cabling. Other features include:

- Automatic calibration and zero tracking

- test mode to test functionality of the sensor

- simulation mode to generate test sequences without trains required.

- Measure train speed to 300 kph

- Majority Logic to forgive 1 missed wheel

- Solar panel operation with wireless communications

Axle Counters For Yards, Crossings, Blocks

The Argenia Solar+Wireless Digital Axle Counting System is a state-of-the-art microprocessor controlled digitizing railway wheel sensor system for urban rail, mainline and train yard applications.

It is the only wheel sensor on the market with solar and wireless capabilities. Using dual sensors, our system can detect train speed up to 300 kph within 0.2%. Our unique majority logic configurations minimize miscounts.

Safe.

- Designed for fail-safe operation

- Does not interfere with track circuits or other vital systems

- Virtual train simulation mode for easy self-test and diagnostics

- Works with any ballast condition

Reliable.

- Low power requirements ideal for solar powered operation

- Protected from EMC/EMI, lightening, UV, shock

- Pre and post data processing provides more reliable detection with fewer resets

- Sensitive electronics are mounted on the wayside away from the vibrations on the track

- Planar PCB magnetic design of the coils allows for a lower profile sensor with less weight without fragile ferrite core

Accurate.

- Speed detection to 0.2% accuracy up to 300 kph using dual sensors

- Detects all wheel flange sizes

- Corrects for miscounts from truck mounted motors and brakes

- Patent-pending majority logic correction corrects for up to 2 wheel miscounts in a block

- Programmable detection threshold to adjust sensitivity

Configurable.

- Function block programming for system logic

- DIP switch selector for sensor address

- DIP switch selector for quadrature pulse mode with a programmable 'long pulse' on detection

- Adjustable mounting bracket does not require drilling of the rail

Block Occupancy Applications

Detecting the occupancy of track blocks is one of the primary applications of Axle Counter Sensors. Sensors are fastened to the rail at the ‘check-in’ and ‘check-out’ points at either end of a section of track creating a ‘block’. The WCU collects waveforms from the sensors and sends digital data to the Evaluator (EVU) for processing. The EVU counts the axles of the train as it enters the block, and again as it leaves, based on the output of the sensors. The EVU will indicate that the block is ‘occupied’ when the first axle passes the ‘check-in’ point. Once the EVU has counted the same number of axles leaving the ‘check-out’ point as it counted at the ‘check-in’, the block is deemed vacant and safe for another train to enter.

Axle-counting-based block occupancy systems are used as an alternative to fixed blocks handled with track circuits. They are also an efficient and effective backup solution for more sophisticated moving block systems common with communications-based train control (CBTC).

Our axle-counting system relies on two sensors at the check-in and check-out points. This provides the data for our unique majority logic algorithm which ensures the highest level of accuracy.

Train Detection in Rail Yards

Freight cars can spend up to two thirds of their transit time sitting idle in yards. Systems that optimize yard management can significantly increase throughput which increases the profitability of a railway. Axle counters are ideal for tracking the movement of rolling stock in yards. Axle counters (sensors) are fastened to the rail at the entry points of each track segment where they detect cars as they come in. Data from the sensors is sent to yard automation systems that assist with the sorting of rolling stock.