Grade Crossing Systems

Grade crossings systems detect trains approaching a roadway crossing and activates the signals and lowers the gates. When the train leaves, it lifts the gates and deactivates the signals and bells. These are common traits of all crossings.

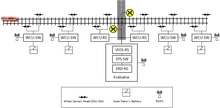

Some crossings need to have 25 seconds of advanced warning so the train must be detected from a long distance. For a train traveling at 100 kph, it must be detected about 1 km away. Sensors at this distance are called the far points, or remote approach sensors. The sensors placed around the roadway are called the island sensors.

For a single track with 25 second advanced warning for the motorist, 4 sensors are needed.

For very slow trains in industrial yards, the approach sensors can be eliminated provided the train entering the island waits until the signals have rung for several seconds and then proceeds only if no immediate traffic.

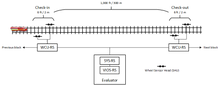

The crossing works on the 'check-in' and 'check-out' procedures. The distance between the sensors is known as a block or zone. When a train enters the zone, (check-in) the wheelcount is determined by counting the number of wheels that entered across the sensor. As the train leaves across the second island sensor (checks-out) the net difference between wheel counts determine if the block is occupied. The crossing will respond when any non-zero wheelcount difference is detected.

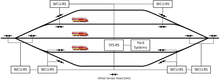

Argenia crossing systems can handle up to 6 tracks which requires 24 sensors. A sensor concentrator such as SilverFox is used to handle all sensors simultaneously.

The main control element is the SilverHawk controller. It reads all track sensors and computes the block occupancy and controls the signal lights and optional gates.

A single SilverHawk controller is designed for SIL 3 operation which is suitable for most crossing systems. If SIL 4 is required, two controllers are joined to make a Two-out-of-two (2oo2) controller with higher risk reduction capability.

The diagram below shows a crossing with both Far-points and Near-point detectors in addition to the island block detectors.

Level / Grade Crossing Applications

Two wheel sensors are placed six feet apart, precise speed measurement is possible. Train position is calculated based on the speed-time integration, allowing the calculation of the progression into the crossing zone. This provides a constant warning time of 25 seconds for any train speed. This is known as a Predictive Crossing configuration.